Classic car restoration is an expanding field in which passion and preciseness are dominant. To achieve perfection when restoring a classic car – and ensuring it can be safely put on the road – restoration workshops have to put forth skills, expertise and overcome constant challenges. This includes the difficulty in finding the needed spare parts. Indeed, for many classic cars, there no longer exist production lines for parts such as door handles, mirrors, and flanges – which are sometimes impossible to find. And some of those are either impossible to repair, when not entirely missing.

Restoration of classic cars and motobikes, from bodywork to mechanical parts

3D printing fixed the problem of missing parts as well as market speculation on these same parts. 3D printing technologies allow for the production of a single part with the same characteristics as the original piece, and with an increased resistance to workloads and heat. By measuring the whole part in three dimensions, so many scans are taken which – when aligned with each other – will confirm the symmetry and overall dimensions of the part by comparing them with any measures available on file at the parent company. If such measures cannot be found, a comparison can be made with other previously produced cars, using a certain tolerance range – given that they are all hand-made. Laser scanning allows the recreation of all the missing parts: door handle, mirror, headlight cover, window hook, air intake vents, interior trim details which are then finished with leather. All of these parts are difficult, impossible to find, or very expensive. Engine parts can also be recreated: a scan is made with the probing arm and a full three-dimensional drawing is generated – which can then be passed directly to the foundry. With Reverse Engineering multiple paths to physically reproduce the item are emerging!

Sheet metal restoration of a classic car

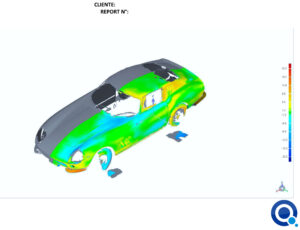

A classic car’s bodywork can reserve unforeseen challenges: one can often find very rusty parts that need to be cut off and rebuilt from the scratch. Thanks to laser scanning a point cloud image is obtained through which one can determine the parts to be fixed, repainted, and grouted. Jigs and support frames can thus be created to assist the coachbuilder in undertaking the body repair operations. This service is customized for each vehicle, and measurements will make the restoration process faster and more reliable, avoiding unpleasant surprises.

Emilia, Land of Motors

Controllo Qualità srl successfully cooperates with the leading classic car and motorcycle restoration workshops, such as Brandoli Egidio srl or Cremonini Classic. To find out about our 3D printing service for classic car restoration workshops, contact us!